When you're working on any sort of engineering project, you will always have some sort of restriction/constraints. Blank checks don't exist for anybody - and that will be the same for robotics. A Bill of Materials helps to keep you in-line with that restriction by keeping track of the cost, amount of components in your system, and what materials they are made of to create a copy of your Robot.

Now I don't expect you to know exactly how many screws you have on your robot (that's crazy business) - but the BOM should reflect:

- How many pieces of C-Channel you have used.

- Any other random structural components.

- All the electronics you have on your robot.

- How much plastic (ABS, Acetal, Polycarb), is on your robot.

Since your robot constantly changes throughout the year, it is understadable to not have a perfect BOM representation at all points in the season. But with each new big iteration, you should be able to express how your robot has changed through time.

For cost estimates - always refer to the VEX Robotics website and Robosource Website, as that is where we source all of the materials.

NOTE: YOU DO NOT HAVE TO KEEP TRACK OF SHIPPING COSTS, ONLY THE MATERIALS

Further description from: https://www.projectmanager.com/blog/bill-of-materials

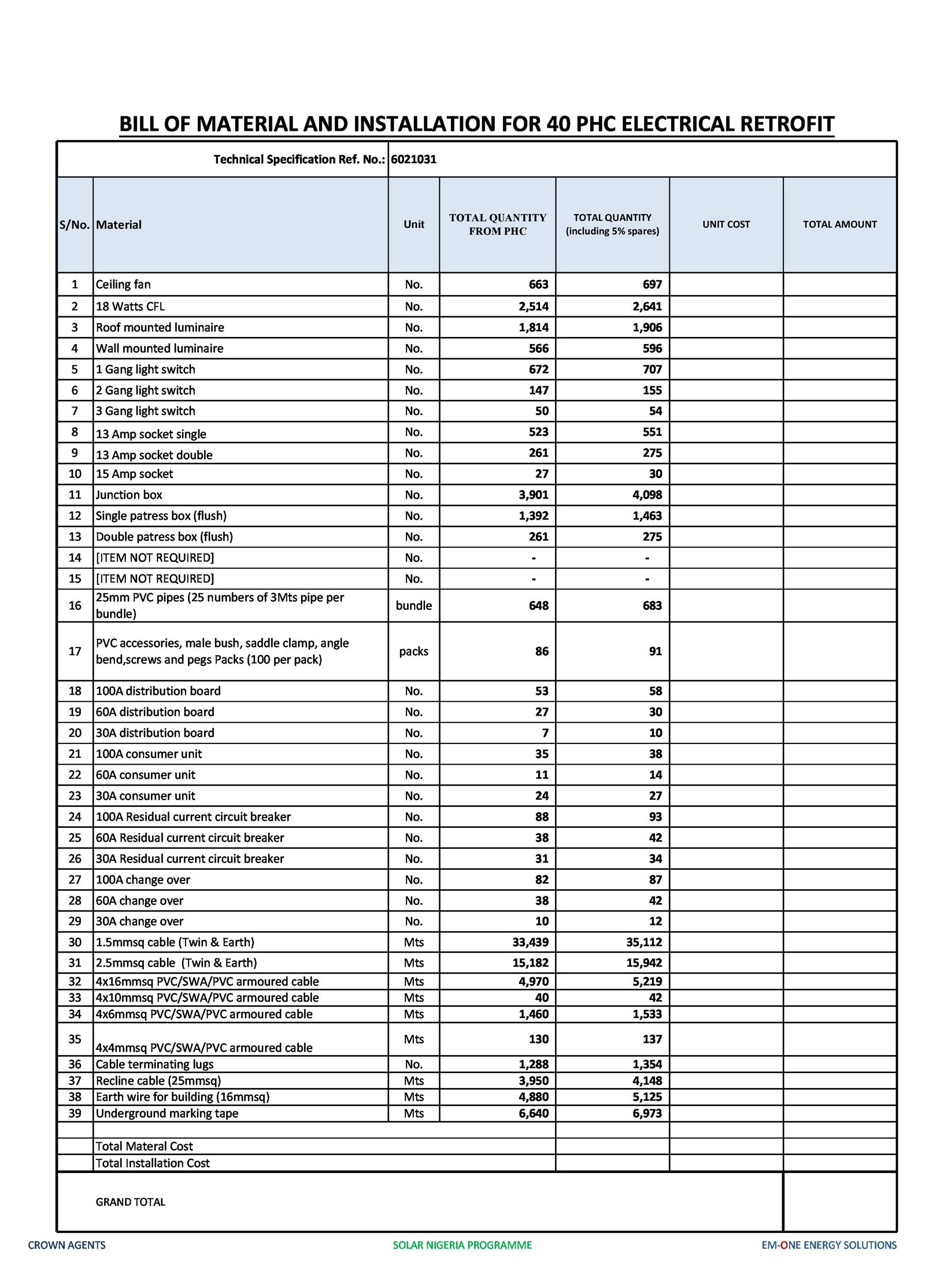

Bill of Materials

A bill of materials (BOM) is the full list of all the materials, components and parts that are required in the manufacturing of a product. The BOM includes how many of each item is needed, with the name, a description and the costs for the item.

As we noted above, the bill of materials is more than a litany of what’s necessary to build the product being manufactured. It’s also an instruction manual of sorts, which explains how to get these materials and how they’ll be used on the production line.

Therefore, the bill of materials can be your central record of everything needed to build your product. It helps you plan what you have to purchase by estimating costs. The BOM also can assist in planning and controlling inventory in order to avoid delays and waste.

BOM LAYOUT EXAMPLE: